Advice, print preparation

Based on your application, we will help you to choose the optimum substrate and printing technology. If necessary, we can also redesign the 3D model in order to ensure its printability or functionality, taking into account the constraints set by the customer.

Printing services

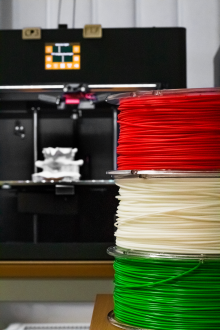

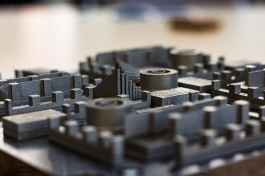

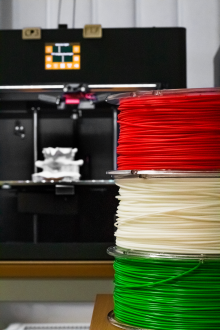

The 3D Centre's fleet of machines can currently deliver solutions for four of the seven 3D printing technologies. From biocompatible resins to thermoplastics and various metal alloys, we can print from a wide range of materials, depending on the nature of the application required.

The 3D Centre's fleet of machines can currently deliver solutions for four of the seven 3D printing technologies. From biocompatible resins to thermoplastics and various metal alloys, we can print from a wide range of materials, depending on the nature of the application required.

You do not need to come with a pre-designed object to contract print: we can also help you draw a 3D model of the object you need, based on a conceptual design you bring to us. In addition, we have a number of other options for creating the initial model: if a 3D copy is required, we can use our 3D scanners or haptic tool to capture the shape of the object to be copied, or, in the case of data from medical imaging procedures, we can use 3DSlicer software to segment and create the 3D model.

Scanning, quality control

With our 3D scanners, we can also create 3D models of objects for external projects, including, if required, the conversion of the point cloud into CAD format. We can compare the resulting 3D scans with virtual models of the objects we print, with virtual models of the elements manufactured by third parties, or even with the geometry of products made using different manufacturing technologies.

With our 3D scanners, we can also create 3D models of objects for external projects, including, if required, the conversion of the point cloud into CAD format. We can compare the resulting 3D scans with virtual models of the objects we print, with virtual models of the elements manufactured by third parties, or even with the geometry of products made using different manufacturing technologies.

In addition, for objects subjected to periodic loading, our electrodynamic mechanical tester allows us to perform tensile and fatigue testing of plastic prototypes.

Heat treatment

In our argon/nitrogen shielded gas annealing furnace heated to 1100°C, it is possible to carry out stress relief and annealing heat treatments on alloys (e.g. aluminium, titanium) sensitive to impurities (oxygen, hydrogen, nitrogen) without brittleness of the surface and thus without major deterioration of the fatigue strength of the sample.

Training

Upon prior arrangement, we can provide customized training, including practical training on the 3D Centre's equipment, for groups of companies or vocational training institutions that require technology-specific training in 3D printing, visualization and design.

Visit to the 3D Center

Groups or individuals can visit the 3D Centre by prior arrangement. During the visit you can see the workflow, printers and other equipment in operation. On request, we can also provide a venue for field trips, outsourced lessons or even team-building training.

You can read more about our tools in our Competences section. If you have any questions, please feel free to contact us.

The 3D Centre's fleet of machines can currently deliver solutions for four of the seven 3D printing technologies. From biocompatible resins to thermoplastics and various metal alloys, we can print from a wide range of materials, depending on the nature of the application required.

The 3D Centre's fleet of machines can currently deliver solutions for four of the seven 3D printing technologies. From biocompatible resins to thermoplastics and various metal alloys, we can print from a wide range of materials, depending on the nature of the application required. With our 3D scanners, we can also create 3D models of objects for external projects, including, if required, the conversion of the point cloud into CAD format. We can compare the resulting 3D scans with virtual models of the objects we print, with virtual models of the elements manufactured by third parties, or even with the geometry of products made using different manufacturing technologies.

With our 3D scanners, we can also create 3D models of objects for external projects, including, if required, the conversion of the point cloud into CAD format. We can compare the resulting 3D scans with virtual models of the objects we print, with virtual models of the elements manufactured by third parties, or even with the geometry of products made using different manufacturing technologies.