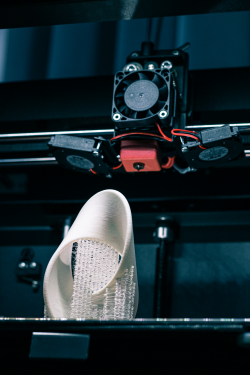

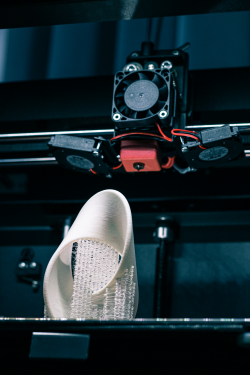

Craftbot Plus (FDM – Fused Deposition Modelling)

Fused filament printers are already in common use, and although they are the cheapest solution for printing lower resolution models (ornaments, concepts), the mechanical properties of the printed objects can approach the quality of models made with classical technologies. Our Craftbot Plus printers with heated platform can work with 1.75 mm diameter filament, easy to handle PLA, ABS, PETG and many other materials.

Fused filament printers are already in common use, and although they are the cheapest solution for printing lower resolution models (ornaments, concepts), the mechanical properties of the printed objects can approach the quality of models made with classical technologies. Our Craftbot Plus printers with heated platform can work with 1.75 mm diameter filament, easy to handle PLA, ABS, PETG and many other materials.

Key features:

Max tray temperature: 110°C

Max print/nozzle temperature: 300°C

Min. layer thickness: 100 µm

Lateral resolution: 100 µm

Working space dimensions (X×Y×Z): 250mm×200mm×200mm

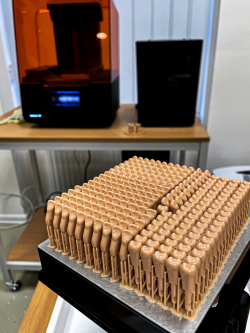

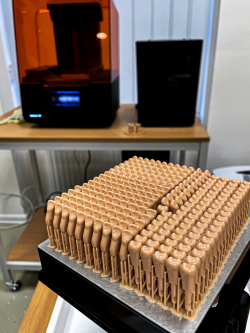

Formlabs Form3 (LFS – Low Force Sterolithography)

With our Form3 desktop printer, you can print detailed products using flexible, heat-resistant or even dental photopolymer resins to create a smooth to the touch surface.

With our Form3 desktop printer, you can print detailed products using flexible, heat-resistant or even dental photopolymer resins to create a smooth to the touch surface.

Key features:

Min. layer thickness: 50 µm

Lateral resolution: 20 µm

Minimum wall thickness: 100 µm

Working space dimensions (X×Y×Z): 145mm×145mm×185mm

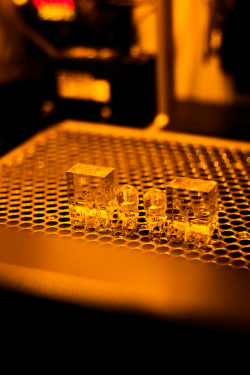

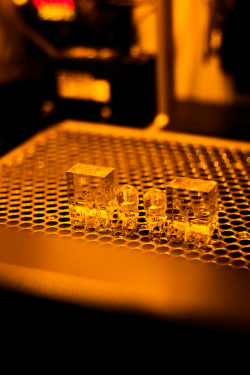

3Dsystems ProJet 6000-HD (SLA – Stereolithography)

The ProJet 6000 professional industrial printer is capable of printing objects with a homogeneous surface quality at a resolution of 20 µm on a wide range of substrates (e.g. heat-resistant, ABS, polycarbonate-like, etc.), even Class VI biocompatible plastics.

The ProJet 6000 professional industrial printer is capable of printing objects with a homogeneous surface quality at a resolution of 20 µm on a wide range of substrates (e.g. heat-resistant, ABS, polycarbonate-like, etc.), even Class VI biocompatible plastics.

Key features:

Min. layer thickness: 50 µm

Lateral resolution: 20 µm

Minimum wall thickness: 80 µm

Working space dimensions (X×Y×Z): 250mm×250mm×250mm

3DSystems ProJet MJP 3600 (MJP – Multijet Printing)

The advantage of Multijet technology, which works on a similar principle to inkjet printers, is that it offers complete geometric freedom in the shape of the printed object thanks to its readable support. It has the smallest voxel size of any of our printers, which means that the print can be built up from the smallest spatial elements.

The advantage of Multijet technology, which works on a similar principle to inkjet printers, is that it offers complete geometric freedom in the shape of the printed object thanks to its readable support. It has the smallest voxel size of any of our printers, which means that the print can be built up from the smallest spatial elements.

Key features:

Min. layer thickness: 16 µm

Lateral resolution: 34 µm

Minimum wall thickness: 34 µm

Working space dimensions (X×Y×Z): 298mm×185mm×203mm

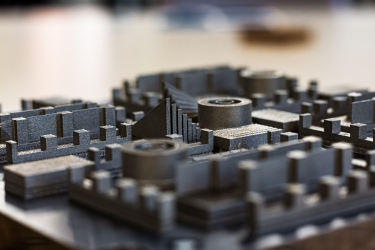

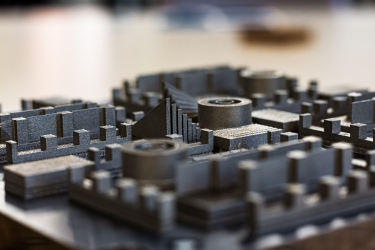

EOS M290 (L-PBF – Laser Powder Bed Fusion)

Our centre's metal printer uses one of the most sophisticated and one of the highest resolution metal printing technologies to date, laser powder bed fusion (L-PBF), fusing layers of powder a few tens of µm thick to create a printed body. In addition to stainless austenitic steel, which has well-balanced mechanical properties and excellent corrosion resistance, nearly thirty alloys are available, including, of course, titanium and cobalt-chromium alloys used for medical and dental implants.

Our centre's metal printer uses one of the most sophisticated and one of the highest resolution metal printing technologies to date, laser powder bed fusion (L-PBF), fusing layers of powder a few tens of µm thick to create a printed body. In addition to stainless austenitic steel, which has well-balanced mechanical properties and excellent corrosion resistance, nearly thirty alloys are available, including, of course, titanium and cobalt-chromium alloys used for medical and dental implants.

Key features:

Min. layer thickness: 20 µm

Lateral resolution: 50 µm

Minimum wall thickness: 200 µm

Work area dimensions (X×Y×Z): 250mm×250mm×325mm

Fused filament printers are already in common use, and although they are the cheapest solution for printing lower resolution models (ornaments, concepts), the mechanical properties of the printed objects can approach the quality of models made with classical technologies. Our Craftbot Plus printers with heated platform can work with 1.75 mm diameter filament, easy to handle PLA, ABS, PETG and many other materials.

Fused filament printers are already in common use, and although they are the cheapest solution for printing lower resolution models (ornaments, concepts), the mechanical properties of the printed objects can approach the quality of models made with classical technologies. Our Craftbot Plus printers with heated platform can work with 1.75 mm diameter filament, easy to handle PLA, ABS, PETG and many other materials. With our Form3 desktop printer, you can print detailed products using flexible, heat-resistant or even dental photopolymer resins to create a smooth to the touch surface.

With our Form3 desktop printer, you can print detailed products using flexible, heat-resistant or even dental photopolymer resins to create a smooth to the touch surface. The ProJet 6000 professional industrial printer is capable of printing objects with a homogeneous surface quality at a resolution of 20 µm on a wide range of substrates (e.g. heat-resistant, ABS, polycarbonate-like, etc.), even Class VI biocompatible plastics.

The ProJet 6000 professional industrial printer is capable of printing objects with a homogeneous surface quality at a resolution of 20 µm on a wide range of substrates (e.g. heat-resistant, ABS, polycarbonate-like, etc.), even Class VI biocompatible plastics. The advantage of Multijet technology, which works on a similar principle to inkjet printers, is that it offers complete geometric freedom in the shape of the printed object thanks to its readable support. It has the smallest voxel size of any of our printers, which means that the print can be built up from the smallest spatial elements.

The advantage of Multijet technology, which works on a similar principle to inkjet printers, is that it offers complete geometric freedom in the shape of the printed object thanks to its readable support. It has the smallest voxel size of any of our printers, which means that the print can be built up from the smallest spatial elements. Our centre's metal printer uses one of the most sophisticated and one of the highest resolution metal printing technologies to date, laser powder bed fusion (L-PBF), fusing layers of powder a few tens of µm thick to create a printed body. In addition to stainless austenitic steel, which has well-balanced mechanical properties and excellent corrosion resistance, nearly thirty alloys are available, including, of course, titanium and cobalt-chromium alloys used for medical and dental implants.

Our centre's metal printer uses one of the most sophisticated and one of the highest resolution metal printing technologies to date, laser powder bed fusion (L-PBF), fusing layers of powder a few tens of µm thick to create a printed body. In addition to stainless austenitic steel, which has well-balanced mechanical properties and excellent corrosion resistance, nearly thirty alloys are available, including, of course, titanium and cobalt-chromium alloys used for medical and dental implants.